Your Global Automation Partner

DIGITAL INNOVATION PARK

Inovace v oblasti průmyslové automatizace se objevují rychleji než kdykoli předtím. Navštivte náš Digital Innovation Park, aby vám nic neuniklo. Získejte pravidelné aktualizace široké škály vzrušujících trendů a našich nejnovějších inovací pro Průmysl 4.0 a IIoT. Vždy to stojí za ten výlet! #DIGITALINNOVATIONPARK

Udržitelná digitalizační řešení pro průmysl

Další témata a novinky

Inovativní automatizace pro inovace v automobilovém průmyslu

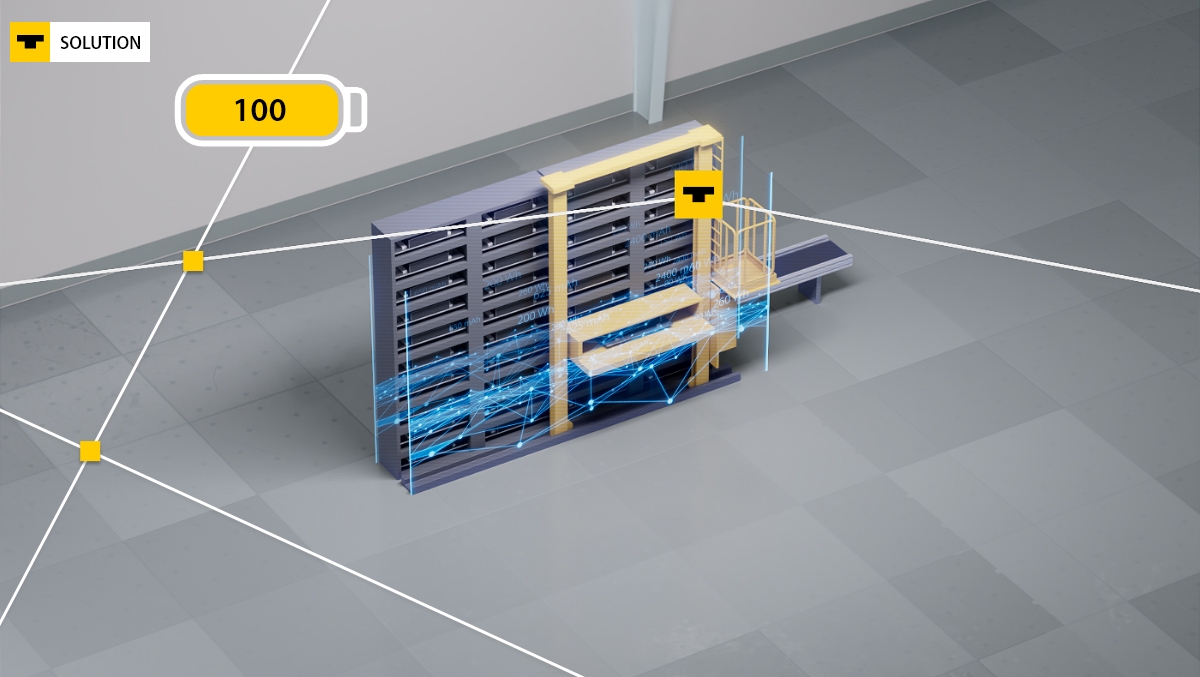

Ať už je mobilita budoucnosti jakákoli, inteligentní automatizační řešení společnosti Turck zajistí efektivní a flexibilní výrobu. Elektromobily poháněné bateriemi, plug-in hybridy a vozidla s palivovými články (New Energy Vehicles, zkráceně NEV) přinášejí do automobilového průmyslu zásadní změnu. Vzhledem k tomu, že důležitými tématy se stávají také individualizace, lehké konstrukce a modularizace, vyžaduje tato nová realita flexibilní výrobní koncepty a inteligentní automatizaci.

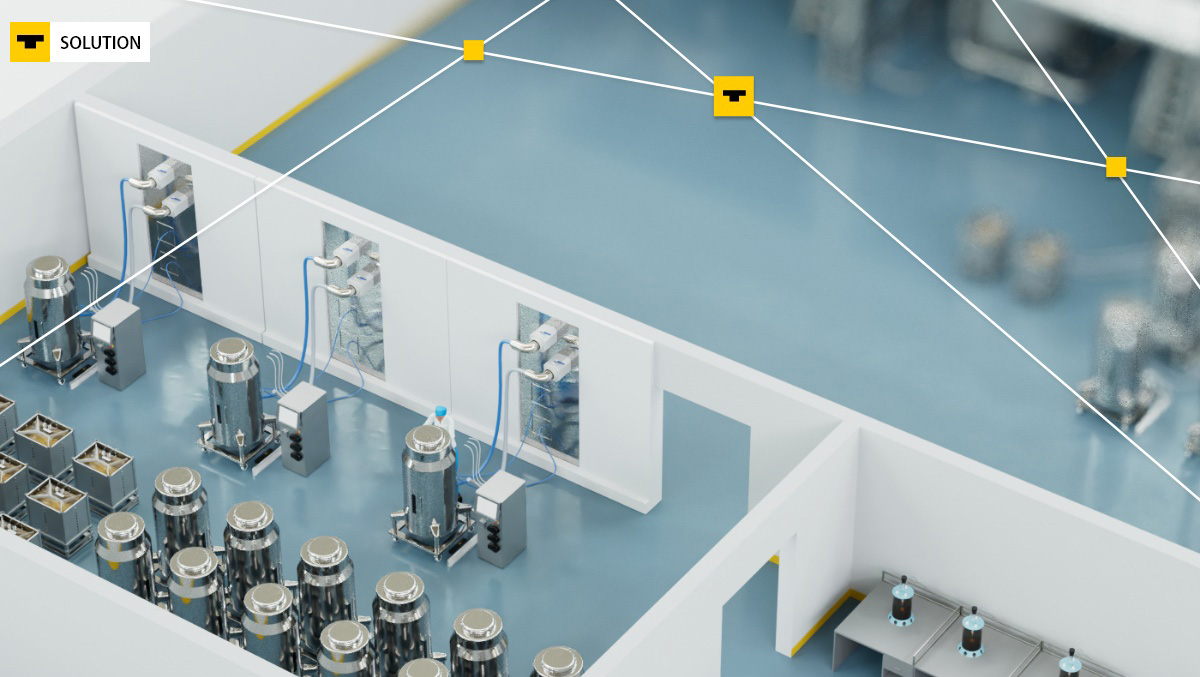

Získejte nezávislost na řídících systémech svých zákazníků

Rostoucí poptávka po léčivých přípravcích představuje pro biotechnologický a farmaceutický průmysl výzvu: je třeba rychle reagovat na potřeby trhu a zkrátit dobu uvedení nového zařízení na trh (TTM). Jak ale urychlit vývoj, výrobu a montáž modulů? Pomocí multiprotokolového Ethernetu. Integrace Profinetu, Ethernetu/IP a Modbusu TCP v jedné technologii umožňuje integrátorům a výrobcům API kombinovat moduly od různých výrobců s různými řídicími systémy.

Senzory Fluid+

Pravděpodobně nejlepší rodina snímačů tlaku, teploty, průtoku a hladiny. Zní to chlubivě? Posuďte sami. Žádný jiný výrobce automatizační techniky nevyvinul technologii snímačů kapalin, která by detekovala všechny čtyři měřené veličiny - průtok, tlak, teplotu a hladinu - pomocí rodiny snímačů od jediného výrobce.

SPE a APL: Zaměření na konektivitu 4.0

SPE a APL budou utvářet budoucnost průmyslové komunikace. O přesné podobě se v současné době diskutuje a definuje ve vývojových odděleních společností zabývajících se automatizací a konektivitou. Rádi bychom vás pozvali, abyste se podíleli na utváření této technologie a abyste s námi hovořili o svých požadavcích a nabídce našich řešení.

Ideální cesta k bezpečnému stroji

Decentralizovaná bezpečnostní technologie vytváří svobodu pro konstruktéry prostřednictvím bezpečnostních řešení pro modulární výrobu. Bezpečnostní moduly s krytím IP67 a integrovanými bezpečnostními řídicími jednotkami odstraňují potřebu rozváděčů a umožňují offline testování bezpečnostních funkcí pro rychlejší uvedení do provozu u zákazníka.

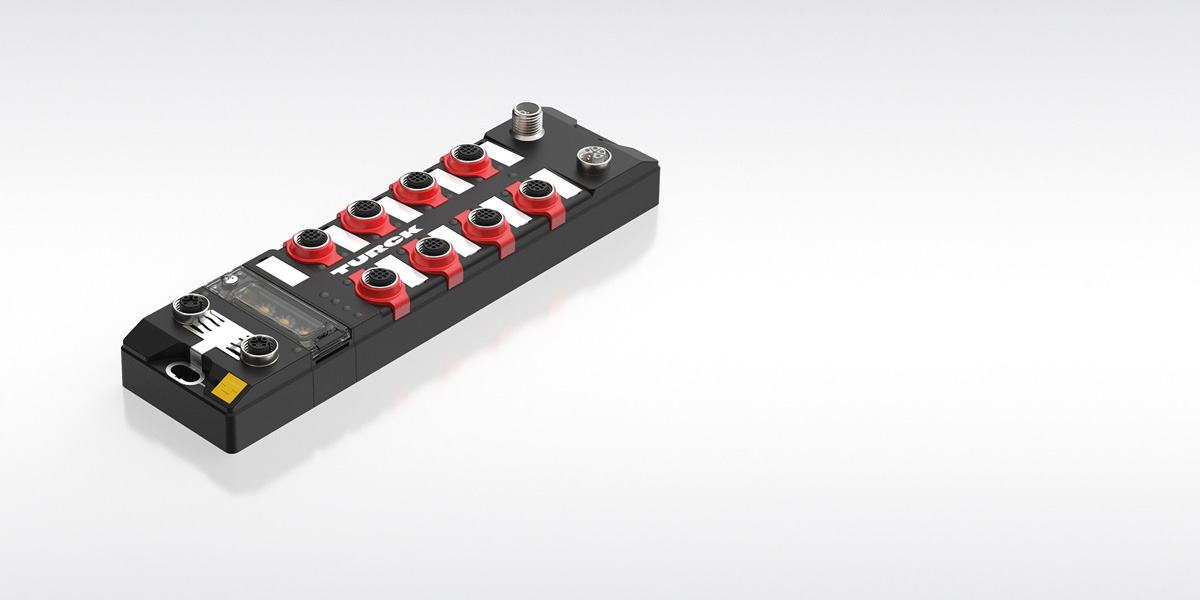

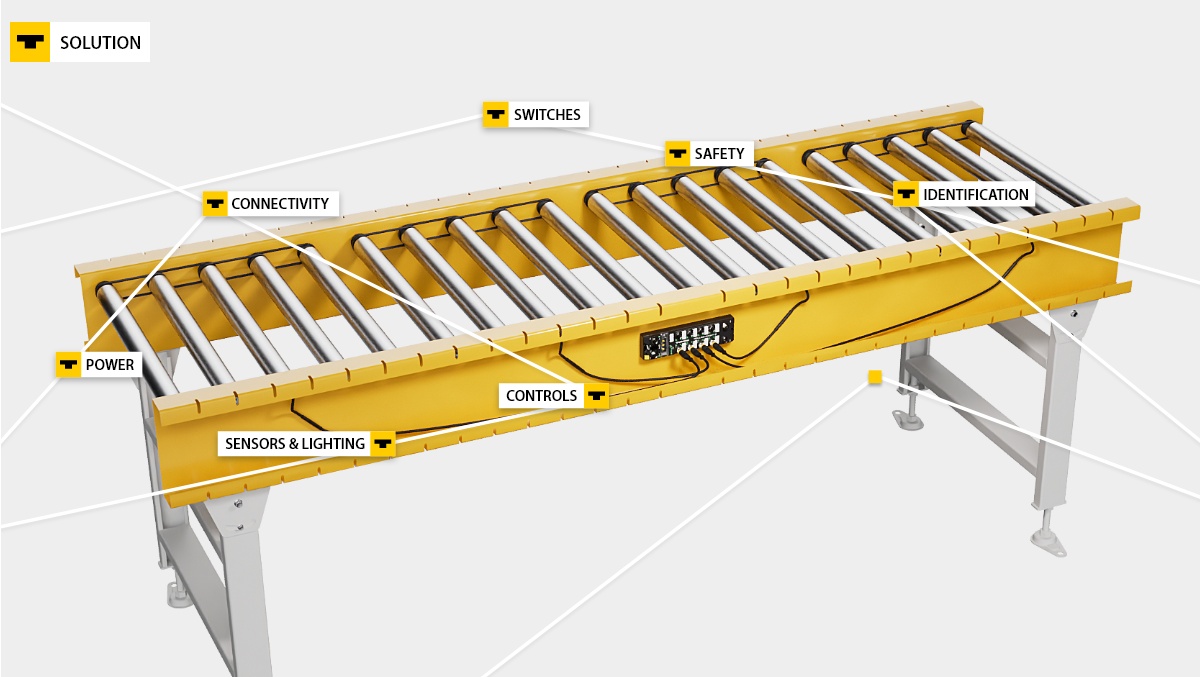

Blok po bloku k flexibilní intralogistice

Modulární dopravníkové systémy vyžadují výkonná řídicí řešení v terénu. Edge kontroléry Turck a blokové I/O moduly v IP67 dělají decentralizovaná rozhodnutí o dílčích procesech. Tím se nejen sníží zatížení hlavního PLC, ale také se zrychlí uvedení do provozu.

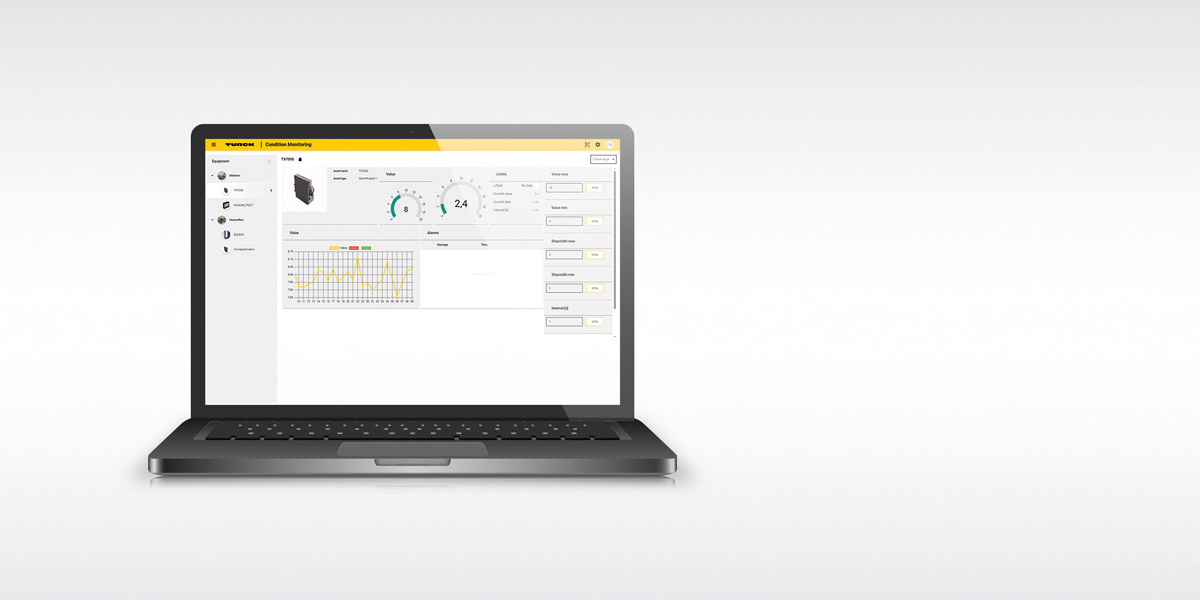

Doplnění monitorování stavu

Autonomní systémy využívající přesnou senzorickou technologii a zabezpečené bezdrátové sítě připravují stávající závody na monitorování stavu. Retrofitní řešení Turck nemá žádný vliv na běžící procesy. Chcete data používat lokálně nebo je posílat do cloudu? Volba je jen na vás!

Ethernet v Ex prostředí

excom Ethernet umožňuje přenášet a analyzovat procesní a stavová data současně až do zóny 0 - bez jakéhokoli zásahu do stávajících řídicích systémů. Umožňuje to ethernetová brána GEN s možností paralelního přístupu k datům. Umožňuje přenášet procesní informace spolu s uživatelskými daty do externích IT systémů - a připravit se tak na inteligentní monitorování stavu a prediktivní údržbu.

Stroj promlouvá: IO-Link

Obousměrné rozhraní IO-Link je klíčové pro optimalizaci digitálních procesů. Ať už se jedná o výměnu senzorů typu plug-and-play, diagnostiku stavu stroje nebo senzorů nebo identifikaci zařízení, rozhraní IO-Link je nezbytné pro vytvoření cesty k efektivní digitální výrobě.

Cloudové služby optimalizované pro průmysl

Řešení Turck Cloud Solutions byla vyvinuta tak, aby splňovala požadavky průmyslových zákazníků na IIoT. Mezi tyto požadavky patří šifrovaná komunikace pro maximální bezpečnost, plug-and-play ovládací panely pro vzdálenou údržbu nebo automatická hlášení alarmů. Dokonalý cloud pro průmyslové aplikace - hostovaný společností Turck nebo na serverech vlastněných zákazníkem.

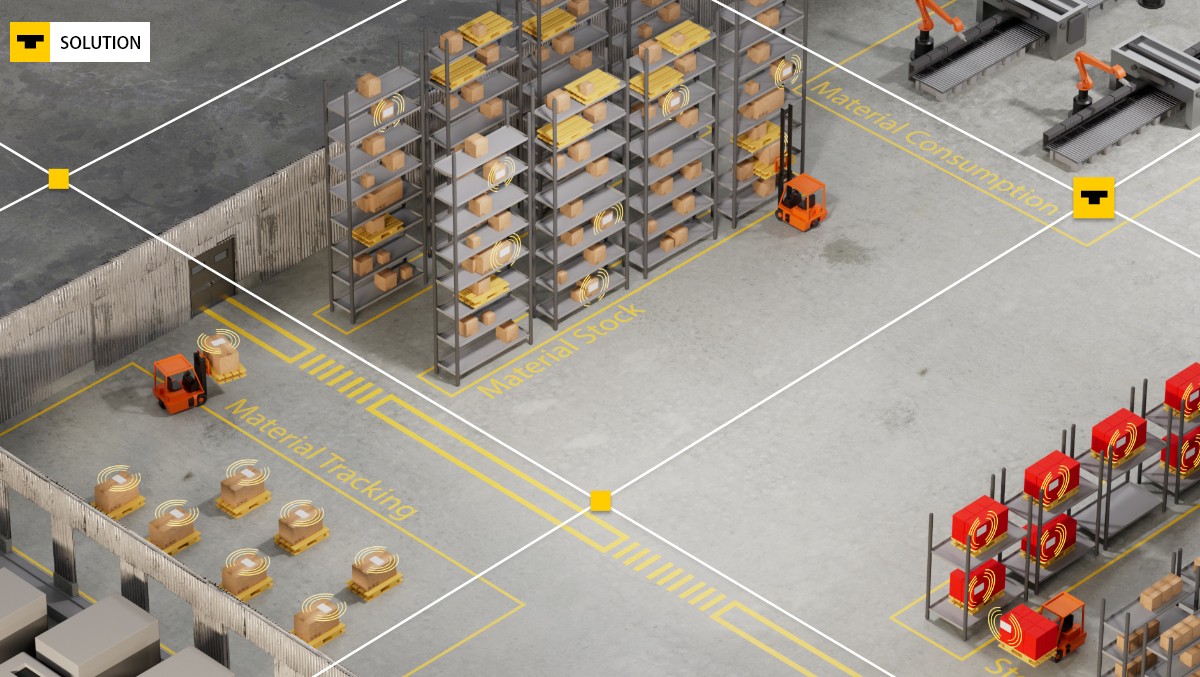

Transparentnost ve výrobě a logistice

Systémy RFID identifikují a lokalizují zboží od fáze příjmu zboží a výroby až po maloobchodní prodej. Společnost Turck kombinuje své rozsáhlé portfolio technologií RFID s krytím IP67 v pásmu HF a UHF s integračními znalostmi společnosti Turck Vilant Systems, což z ní činí jednoho z předních specialistů v oboru.

Oddělit, napájet, chránit - i v té nejmenší rozvodné skříni

Moduly IMXK byly speciálně vyvinuty pro instalaci do plochých rozváděčů. Jsou stejně úzké jako standardní zařízení, ale díky hloubce 77 mm se vejdou i do kompaktních rozváděčů a jiných malých skříní.

Vysoká šířka pásma pro průmysl 4.0

Ethernetový přepínač TBEN-L-SE-M2 s krytím IP67 a vysokorychlostní páteří Gbit umožňuje nejkratší dobu propojení a rychlý tok dat z I/O modulů, motorů a IP kamer. Přepínač poskytuje maximální zabezpečení díky vestavěnému firewallu, směrování NAT a virtuálním sítím LAN (VLAN).

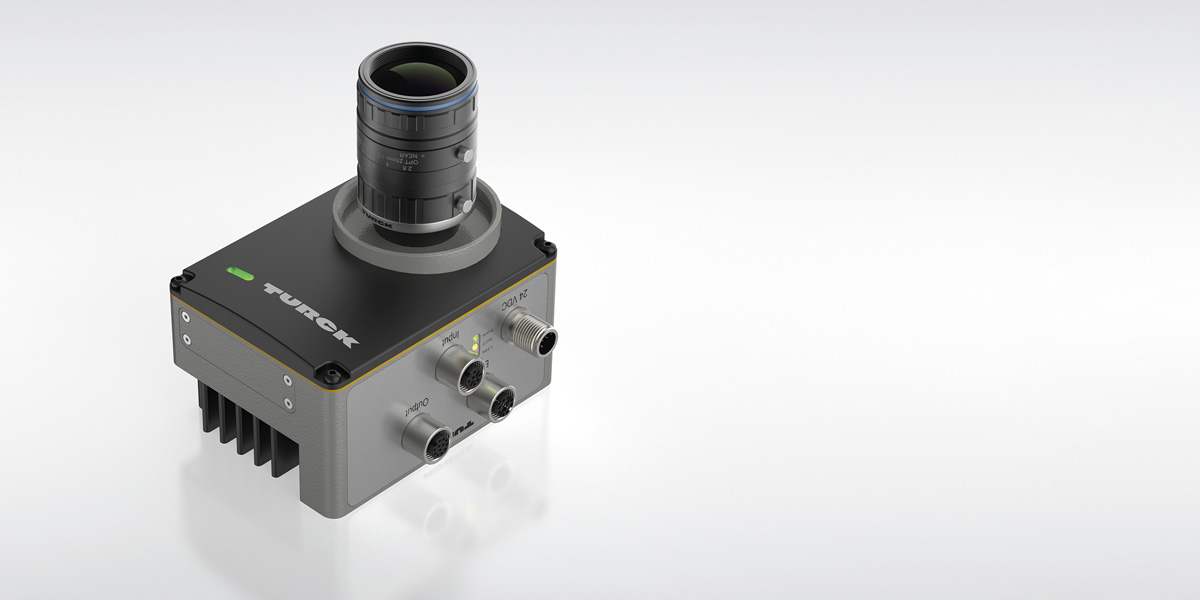

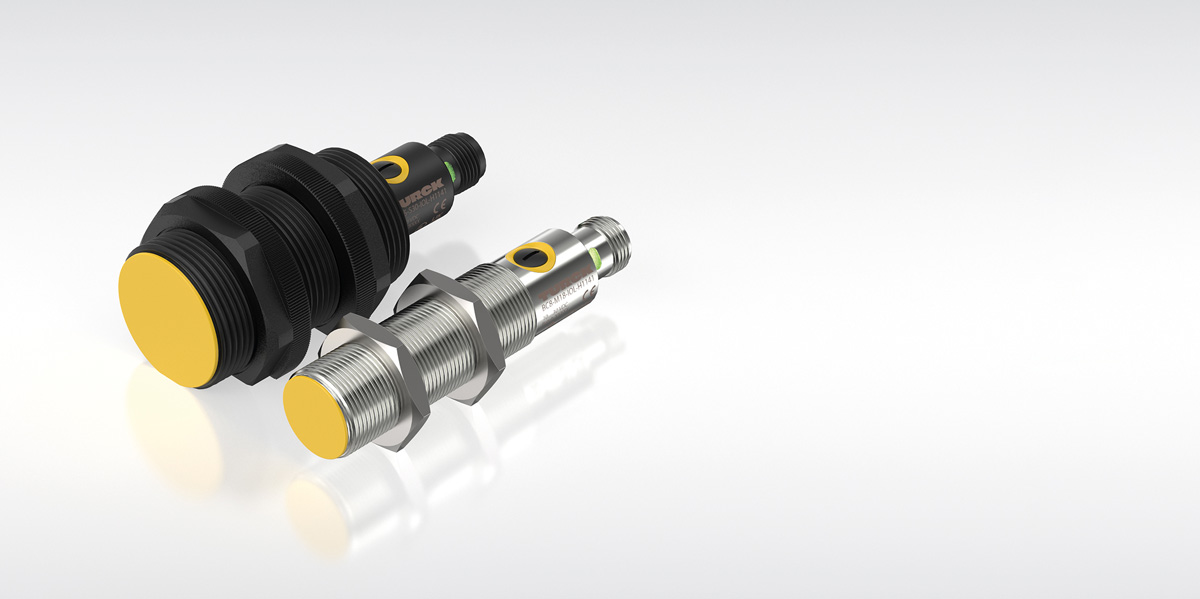

Senzorová řešení - všestranná a inteligentní

Měření polohy a vzdálenosti nebo detekce objektů a kapalin - náročné úlohy v automatizaci vyžadují chytrá řešení. Společnost Turck má proto ve svém sortimentu snímače, které jsou nejen mimořádně robustní a přesné, ale díky rozhraní IO-Link se z nich stávají chytré a všestranné přístroje.

Inteligentní kontrola průtoku

Kontrola Delta a funkce Quick-Teach usnadňují uvedení snímače průtoku FS+ do provozu. Intuitivní koncepce ovládání s kapacitními tlačítky zajišťuje odolnost přístroje až do stupně krytí IP6K9K, aniž by to bylo na úkor skvělého vzhledu. A díky modulární mechanické koncepci je vhodný snímač FS+ k dispozici v nejkratší možné době.

Rychle najděte ten pravý: Snímače od společnosti Turck

Rotační snímač by měl fungovat způsobem, který nejlépe vyhovuje dané aplikaci. Portfolio společnosti Turck sahá od klasických až po prémiové snímače schopné provádět bezkontaktní měření. Klíčovými kritérii při výběru vhodného snímače jsou typ výstupu a velikost příruby, stejně jako typ a průměr hřídele.

Následujte nás

Přejete si být pravidelně informováni o Digitálních Inovacích?

Sledujte hashtag na sociálních médiích. Už nikdy nezmeškáte novinky o průmyslových trendech, aplikačních zprávách, webinářích a dokumentech o inteligentní automatizaci.